-

Nagrzewnice indukcyjne

-

Urządzenia grzewcze indukcyjne wysokiej częstotliwości

-

Przenośna maszyna indukcyjna indukcyjna

-

PWHT Machine

-

Urządzenia do obróbki cieplnej po spawaniu

-

Indukcyjna maszyna do wypalania

-

Ogrzewanie indukcyjne średniej częstotliwości

-

Maszyna do obróbki cieplnej indukcyjności

-

Maszyna do utwardzania indukcyjnego

-

Maszyna do lutowania indukcyjnego

-

Temperatury indukcyjne

-

Odprężenie indukcyjne

-

Urządzenia grzewcze indukcyjne

-

Spawarka punktowa termoelektryczna

| Miejsce pochodzenia | Shenzhen Chiny |

|---|---|

| Nazwa handlowa | canroon |

| Orzecznictwo | CE ISO9001:2008 |

| Numer modelu | CR2000 |

| Minimalne zamówienie | 1 kawałek |

| Cena | Negotiable price |

| Szczegóły pakowania | Karton lub zależy od Ciebie |

| Czas dostawy | Tydzień po potwierdzeniu płatności |

| Zasady płatności | KIESZONKA NA ZEGAREK |

| Możliwość Supply | 20 sztuk / sztuk na tydzień |

| Model kontrolny | Kontrola cyfrowa | Moc wejściowa | 380 V 3-faza |

|---|---|---|---|

| Rezonans | Rezonans serii | Temperatura | MAX 1450 ° F. |

| Transport | Drogą morską lub powietrzem | Ocenione wyjście | 80kW 1-35 kHz |

| Zastosowania | Do rur stalowych konstrukcyjnych | Tryb chłodzenia | SPRAWDZIone powietrze |

| Podkreślić | induction preheater for welding,induction hardening machine with warranty,uniform heating induction preheater |

||

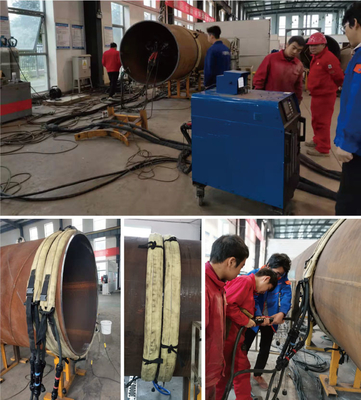

80Kw Preheating Induction Hardening Machine For Structural Steel Tube to 300°F

Quick Detail:

Type:Other

Place of Origin:China (Mainland)

Brand Name:Canroon

Model Number:CR2000-080A-14T

Voltage:380V

Current:122A

Rated Capacity:80KW

Rated Duty Cycle:80KW

Dimensions:880*663*982

Weight:201Kg

Usage:induction temperature stress relievers

Certification:CE ISO9001:2008

After-sales Service Provided:Overseas service center available

Process:Induction heating equipment

Input Power:380V,3-Phase

Temperature recorder:6 Channel temperature recorder

Description:

Move beyond conventional limits. The CR2000 combines air-cooled operation (up to 1450°F) with intelligent features to eliminate hotspots and delays. Its six-zone thermal control guarantees uniformity, while the programmable interface and built-in coaching empower any operator to achieve peak coil performance and flawless ramp/hold cycles with ease.

Applications:

With the introduction of the Induction Pipe preheat , this simple and cost-effective heating process can be applied in the following applications to deliver fast and consistent heat:

- Welding fabrication and construction;

- Preheating of welds;

- Post-weld heat treatment;

- Coating removal;

- Shrink Fit and so on

- Pre-heating of structural steel tube to 300°F

Specifications:

|

Input Amperes at Rated Output |

380V:122A |

|

Thermal conversion efficiency |

More than 90% |

|

Maximum Rated output |

80KW |

|

Cooling Mode |

Air cooled |

|

Input Power |

380V 3-Phase,50HZ |

|

Rated Output |

80KW at 100% duty cycle,1-35KHZ |

|

TC input |

6 circuit |

|

Digital Recorder |

Optional |

|

Control Model |

Digital Control |

|

Resonance |

Series Resonance |

|

Temperature |

Max 1450°F |

|

Dimensions |

H:880MM W:663MM D:982MM |

|

Transportation |

By sea or By Air |

|

Weight |

201KG |

|

Warranty |

12 Months |

Competitive Advantage:

-

Unmatched Process Control & Quality

-

Uniform Heating: Multi-thermocouple inputs ensure quality by auto-adjusting to the hottest/coolest points.

-

Deep, Consistent Results: Induction heats from within the material, preventing surface marring and ensuring uniformity.

-

Precision Programming: Simple interface allows for manual or automated ramp/hold cycles.

-

-

Maximum Operational Efficiency

-

Rapid Time-to-Temperature: Induction heating is significantly faster than conventional methods.

-

High Energy Efficiency: Over 90% system efficiency transfers more energy to the part, reducing costs.

-

Easy Setup: Utilizes flexible heating cables and user-friendly insulation blankets for quick deployment.

-

-

Superior Economic Value

-

Low Consumable Costs: No fuel, and reusable insulation (50+ uses) drastically cuts recurring expenses.

-

Reduced Downtime: Faster heating cycles and quick setup increase overall project throughput.

-

-

Enhanced Safety & Usability

-

Inherently Safer Environment: No open flames, explosive gases, or exposed hot elements.

-

Foolproof Safety Systems: Open output detection and isolation fault protection prevent unsafe operation.

-

Versatile Mobility: Optional running gear enables easy transport to various job sites.

-